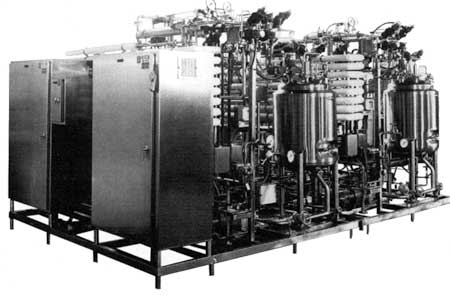

HARTEL BDN SYSTEMS utilize a combination of receiver and treatment tanks to neutralize contaminated solutions safely and effectively. The receiver tank(s) accepts waste, then transfers it to a treatment tank(s) where neutralization takes place by the addition of caustic or acid (pH adjustment) and/or by applying steam (temperature sterilization) to the tank’s jacket or directly to the interior of the pressure rated tank(s). Complete and uniform mixing and/or heating of tank contents is achieved through agitation or recirculation of the tank’s contents during the lifecycle. If the required pH or temperature is not achieved and maintained for the preset period of time, an alarm will sound and the decontamination/neutralization cycle will be reset.

HARTEL BDN SYSTEMS utilize a combination of receiver and treatment tanks to neutralize contaminated solutions safely and effectively. The receiver tank(s) accepts waste, then transfers it to a treatment tank(s) where neutralization takes place by the addition of caustic or acid (pH adjustment) and/or by applying steam (temperature sterilization) to the tank’s jacket or directly to the interior of the pressure rated tank(s). Complete and uniform mixing and/or heating of tank contents is achieved through agitation or recirculation of the tank’s contents during the lifecycle. If the required pH or temperature is not achieved and maintained for the preset period of time, an alarm will sound and the decontamination/neutralization cycle will be reset.

Upon completion of the neutralization cycle in the chemical kill system; waste is discharged directly to the drain. With temperature kill systems, waste is cooled to a predetermined temperature prior to discharging to drain.

- Control panel(s) can be remote or system mounted

- Tanks are available in stainless steel or other materials

- Single-source responsibility

- In-house pre-validation testing prior to installation

- System safety interlocks

- Vertical or horizontal mounted vessels